Curiosity

Today, aluminum is one of the most machined materials. In fact, CNC machining processes of aluminum are second only to steel in terms of frequency. This is primarily due to its excellent machinability. In its purest form, the chemical element aluminum is soft, ductile, non-magnetic, and has a silvery-white appearance. However, the element is not used only in its pure form. Aluminum is typically alloyed with various elements such as manganese, copper, and magnesium, resulting in hundreds of aluminum alloys with significantly enhanced properties.

Advantages of Using Aluminum for CNC

Machined Parts

While there are many aluminum alloys with various levels of properties, there are basic characteristics applicable to nearly all aluminum alloys.

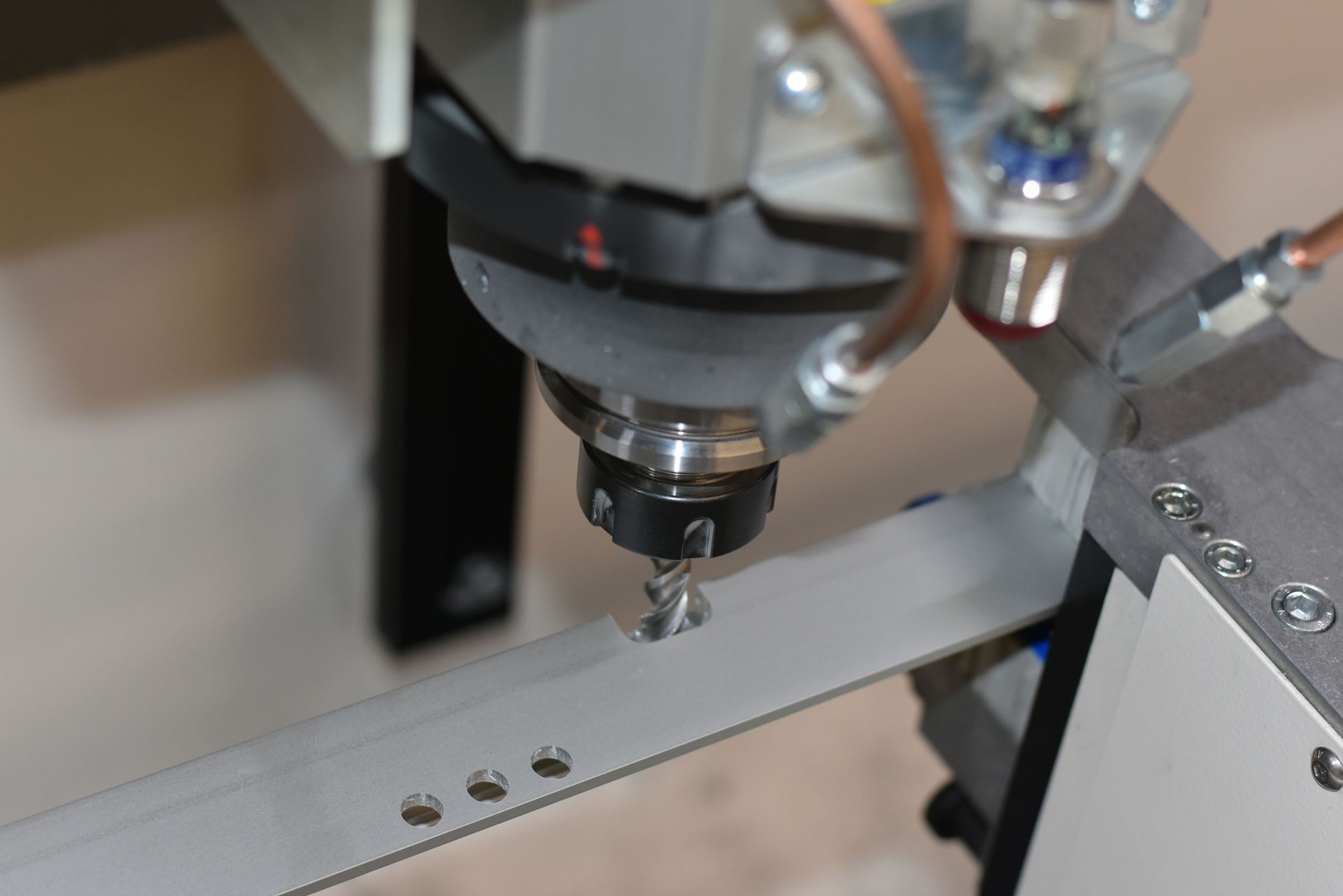

Machinability

Aluminum is easily shaped, processed, and machined using various processes. It can be quickly and easily cut by machining tools as it is soft and fractures easily. It is also cheaper and requires less energy to machine than steel. These properties are a tremendous benefit to both the machinist and the customer ordering the part. Additionally, the good machinability of aluminum means that it deforms less during machining. This leads to higher accuracy as it allows CNC machines to achieve tighter tolerances.

Strength-to-Weight Ratio

Aluminum has about a third of the density of steel. This makes it relatively lightweight. Despite its low weight, aluminum has very high strength. This combination of strength and low weight is described as the strength-to-weight ratio of materials. Thanks to the high strength-to-weight ratio, aluminum is suitable for parts required in several industries, such as the automotive and aerospace industries.

Corrosion Resistance

Aluminum is resistant to scratching and corrosion in common marine and atmospheric conditions. These properties can be improved by anodizing. It is important to note that the corrosion resistance varies among different types of aluminum. However, the most regularly machined grades have the greatest resistance.

Performance at Low Temperatures

Most materials tend to lose some of their desirable properties at temperatures below zero. For example, carbon steel and rubber become brittle at low temperatures. Aluminum, on the other hand, retains its softness, ductility, and strength at very low temperatures.

Electrical Conductivity

The electrical conductivity of pure aluminum is about 37.7 million siemens per meter at room temperature. Although aluminum alloys may have lower conductivity than pure aluminum, they are conductive enough for their parts to be used in electrical components. On the other hand, aluminum would be an unsuitable material if electrical conductivity is not a desirable characteristic of the machined part.

Recyclability

Recycling of aluminum profiles is relatively easy and energy-efficient. The main reason is that aluminum is infinitely recyclable without loss of quality. This means that even after repeated melting and processing, its quality and properties remain unchanged. It helps conserve natural resources, reduces energy consumption, and greenhouse gas emissions compared to producing new aluminum.

References

Top-notch aluminum processing