Technology

MC 319 AYDO – CNC machining center with 3 numerically controlled axes

- Vertical milling center with a moving arm

- For processing profile rods or parts made of aluminum, non-ferrous metals, PVC, and steel

- Array

- 3 CNC controlled axes + 1 pneumatically controlled axis

- Designed for processing on 1 + 2 sides or on 5 sides using an angular head

- Pneumatic rotation of the work table in the range (+)90°-0°-(-90°)

MC 307 FALCON – CNC machining center with 4 numerically controlled axes

- 4-axis CNC machining center for processing profile rods or parts made of aluminum, non-ferrous metals, PVC, and steel

- Processing of the profile from 5 sides through the rotation of the table in the range of 270° (± 135°)

- Magazine for 8 tools

- Range of travel of individual axes

- X-axis (longitudinal): 4275 mm

- Y-axis (transverse): 530 mm

- Z-axis (vertical): 410 mm

- A-axis (rotation of the table): ±135°

2x

MC 309 NIKE – CNC machining center with 3 numerically controlled axes

- 3-axis (X,Y,Z) CNC machining center for processing profile rods or parts made of aluminum, non-ferrous metals, PVC, and steel with one pneumatically rotating A-axis, controlled by a computer

- Processing from 5 sides

- Axis A is the axis of rotation of the spindle with three positions (-90°, 0°, +90°)

- Magazine for 5 tools

- 4 pneumatic clamps

- Range of travel of individual axes:

- X-axis (longitudinal): 3500 mm

- Y-axis (transverse): 370 mm

- Z-axis (vertical): 348 mm

- A-axis (rotating): ±90°

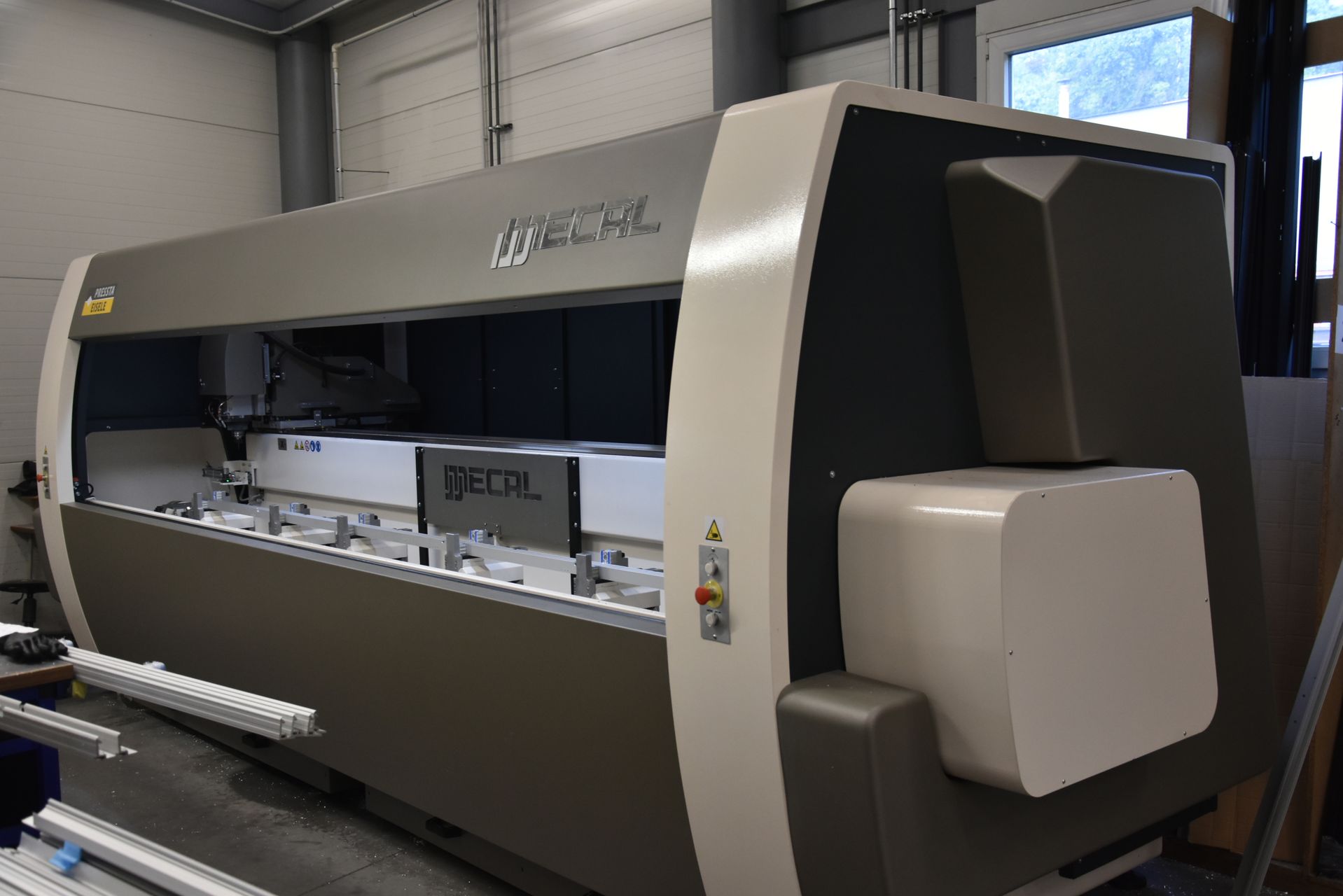

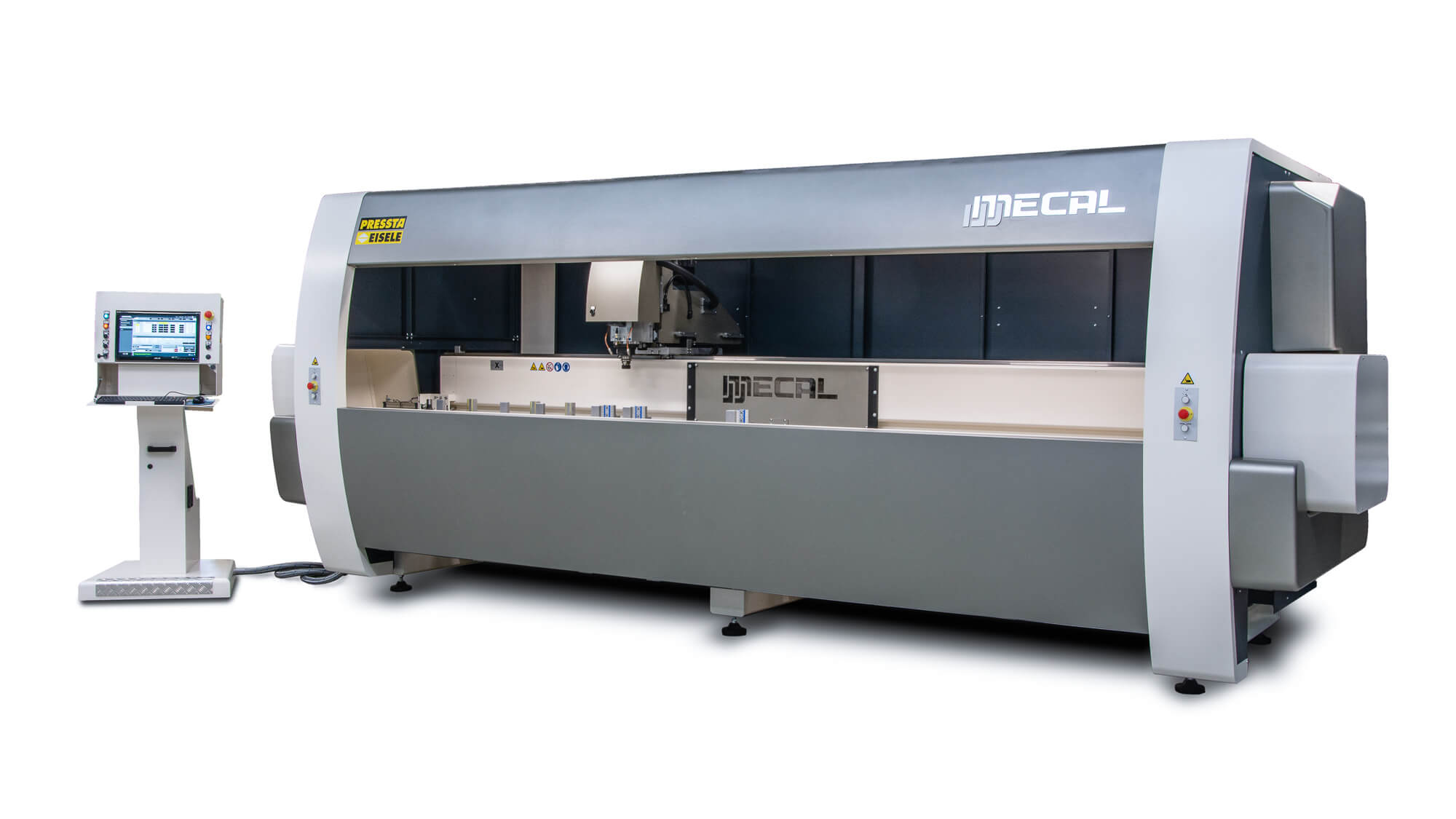

TDC 622 EDGEMASTER – double disc saw

- Precision double disc saw for profiles made of aluminum and PVC

- 5 numerically controlled axes

- Saw blades Ø 600 mm

- Special drive for the movement of the saw blades allows an exceptionally wide range of cutting (lift and then horizontal movement)

- Cutting length up to 6 m

- Motorized rotation of the heads in the range of 22.5°- 90°- 135°

- Motorized tilting in the range of 90°- 45°

- Any cut within the range of the machine programmable

- Hydropneumatic feed with smooth regulation

2x

MASTERWOOD PROJECT 460 – ¾ axis machining center

- Powerful and precise CNC machining center with up to five spindle units

- Double working surface for machining with maximum efficiency and flexibility

- X-axis (longitudinal)5000mm

- Y-axis (transverse)1300mm

- Z-axis (vertical)150mm

CNC Takisawa ex-308 2 axis CNC machining center

- Maximum turning diameter 260 mm

- Maximum turning length 530 mm

- Distance between centers 1645 mm

- Maximum rod diameter 152 mm

- Slanted bed 450 mm

- Maximum spindle speed 4000 rpm

MC 305 KOSMOS TF – CNC machining center with 3 numerically controlled axes

- 4-axis CNC machining center for processing profile rods or parts made of aluminum, non-ferrous metals, PVC, and steel

- Processing of the profile from 5 sides using an angular head

- magazine for 8 tools

- Range of travel of individual axes:

- X-axis (longitudinal): 4225 mm

- Y-axis (transverse): 530 mm

- Z-axis (vertical): 410 mm

Powder and Wet Paint Shop

- 2 powder coating boxes

- 1 box for wet painting

- 2 TKS hardening and drying chambers

Other Technologies

- 8 welding boxes with technology - MAG, TIG, manual arc welding with covered electrode

- Bending press

- Eccentric press

- Electric roll bending machines

- Mechanical band saw

Top-notch aluminum processing